By twisting small fibers, a new device produces changes in temperature. Years from now, it could change the way we cool things down.

–

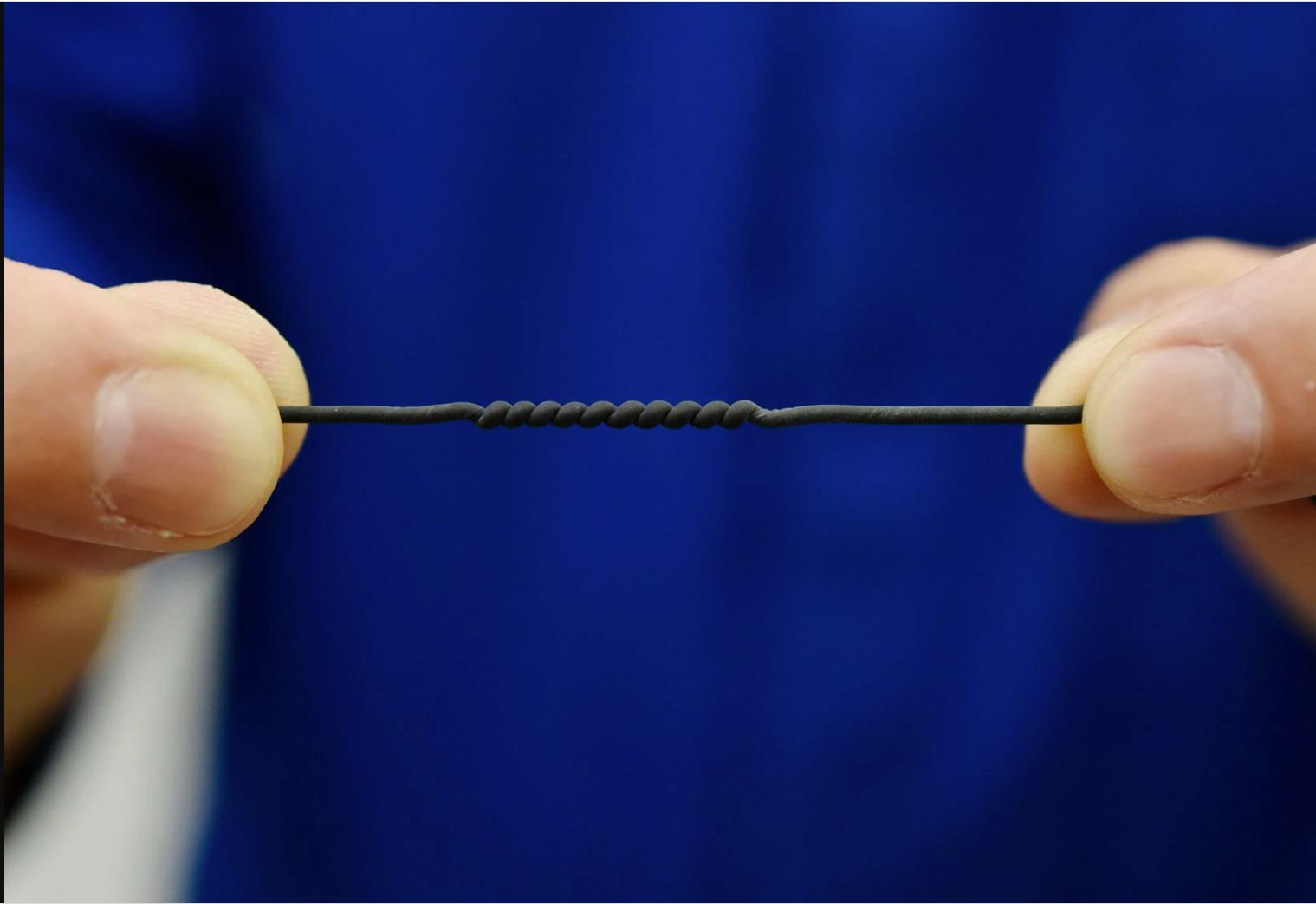

Dallas scientists have developed a fundamentally new approach to cooling things down — by understanding that twisting and untwisting fibers can result in temperature changes. For example, as a thin rubber strand is twisted tightly, the strand gets quite hot. As the rubber untwists, it cools. Researchers at the University of Texas at Dallas affixed fibers such as rubber to a motorized twister that applied a torsional force. The scientists demonstrated their twist on rubber, fishing lines and nickel titanium wire — the same kind of wire used in dental braces. The cooling effect was observed in all of them. The UTD team collaborated with scientists at Nankai University in China to produce the prototype of the cooling device, which they call a “twist fridge.” The findings were recently published in the journal Science. It’s the first time scientists have shown that twisting and untwisting fibers can cause cooling. In the research paper, the scientists demonstrated the effects of twist, also referred to as torsion, on a very small scale. The cooling device is a thin tube as long as a ballpoint pen. Just a few nickel titanium fibers are contained within it.

–

The device can cool about one gram of water by almost 14 degrees Farenheit after one twist-untwist cycle. By comparison, today’s fridges keep their contents around 40 degrees cooler than their surroundings. The research team is working on improvements to lower temperatures even further. And in theory, scaling up the cooler could be as simple as just linking several devices together.

“We’ve already had inquiries from commercial manufacturers for refrigerators interested in our work,” says Ray Baughman, a chemistry professor at UTD and an author of the paper.

Baughman estimates that in just a few years, twist-untwist cooling may be used in special cases when conventional fridges simply can’t be made small enough to work. Their applications could include portable coolers for camping and the cooling of electronic devices such as computers and cellphones. However, it’ll likely be at least another decade before the twist fridge starts seriously competing with conventional refrigerators like those found in kitchens.

The UTD research finding is “definitely high-quality, that’s for sure,” says Jun Cui, a materials science professor at Iowa State University. Cui, who was not involved in the study, says previous studies had explored stretching and unstretching metallic fibers to get a similar effect. But stretching fibers poses a number of problems. First, stretching takes much more effort than twisting to produce the same cooling effect. Second, to get a reasonable cooling effect from stretching alone, there must be room to stretch rubber by four to six times its length. The UTD researchers still stretched the rubber a bit after twisting. But Baughman says that twisting the fiber reduces the extent to which it must be stretched by about a sixth. The twisting of fibers is just the latest approach to replace the current cooling method in refrigerators and air-conditioning units.

Typical refrigerators cool by evaporating a liquid into a gas to dissipate heat from inside the fridge. The gas is compressed then condensed into liquid through coils outside the fridge, causing the heat siphoned from the refrigerator to be expelled outside. Refrigeration and air conditioning, which rely primarily on this vapor-compression cooling, use a fifth of the world’s electricity. That usage is expected to grow as developing countries prosper and as the planet continues to warm, according to the International Institute of Refrigeration, or IIR. “Conventional vapor-compression, I think, has reached the end of its potential,” says Cui. “If we want anything better, more efficient or less environmentally unfriendly, we really need a new platform.”

The twist fridge already shows signs of being moderately more efficient than vapor-compression systems, says Baughman. Given the cooling industry’s immense electricity consumption, “if you can make a fridge that’s 7% more efficient than conventional fridges, what an impact it’d have,” he says. The twist fridge also cuts out conventional fridges’ most direct environmental impact: their cooling fluid. Coolants most commonly used in American refrigerators and air-conditioning units are hydrofluorocarbons — greenhouse gases that are often thousands of times more potent than carbon dioxide. Theoretically, these gases should remain sealed in the fridges’ coils, but “you have paths of the system that can leak,” says the IIR’s general director Didier Coulomb. For big systems with long paths along which the coolant must flow — such as those found in supermarkets — leaks here and there can amount to large emissions, says Didier.

Household refrigerators do tend to be leak-tight. However, these fridges may be discarded without regard for the coolants inside, and as a result, more refrigerants escape into our atmosphere. Because twist fridges work with materials like rubber, instead of coolants, their environmental impact is enticingly lower. The twist fridge is off to a promising start, but there’s a difference between proving that a twist fridge cools and proving that it’s commercially viable. “The main problem is capacity,” says Didier. “Currently, most of these applications are for very small [pieces of] equipment. The capacity is very low. You have some prototypes, but not for big systems.”

There’s also a question about how long fibers can last when they are constantly being twisted. Baughman and his team have shown only that nickel titanium fibers can survive a thousand twists. For a typical refrigerator’s lifetime of a decade or so, however, it’s likely that the fibers must be twisted and untwisted much more. Even so, Cui points out that the damage to these fibers isn’t necessarily a dealbreaker. “For my refrigerator, I change the water filter every half year. … Material damaged? So what? It’s not that expensive to just change it.” At this point, no one knows how long a twist fridge could keep running before the fibers must be switched out.

Baughman says that will be the next problem they seek to address. After all, theirs is only the first demonstration of cooling technology like this. “There are many possibilities for materials that provide even higher performance than we’ve already seen,” he explains. “This is the beginning of the story, not the end.”

–

Article by Jordan Wilkerson

Dallas Morning News

January 23, 2020

You must be logged in to post a comment.