Novel carbon nanotube yarns that convert mechanical movement into electricity more effectively than other material-based energy harvesters have been developed at The University of Texas at Dallas.

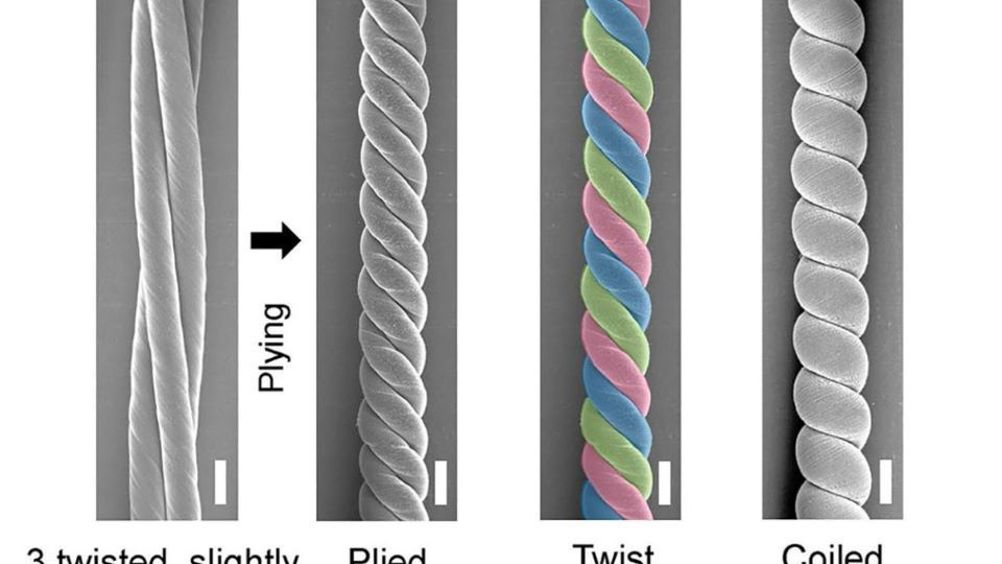

Twistrons, made from spun CNTs, convert mechanical movement into electricity. Scanning electron microscope images show how UT Dallas researchers made a new kind of twistron by intertwining three individual strands of spun carbon nanotube fibres to make a single yarn, similar to the way conventional yarns used in textiles are constructed. A previous version of a harvester (right) was made by coiling the CNT fibres. The scale bars indicate 100 micrometres – UT Dallas

In a study published in Nature Energy, UT Dallas researchers and their collaborators describe improvements to high-tech yarns dubbed ‘twistrons,’ which generate electricity when stretched or twisted.

According to UT Dallas, twistrons sewn into textiles can sense and harvest human motion; when deployed in salt water, twistrons harvest energy from the movement of ocean waves; and twistrons can even charge supercapacitors.

First described by UTD researchers in a study published in 2017 in Science, twistrons are constructed from carbon nanotubes (CNTs) that are twist-spun into high-strength, lightweight fibres, or yarns, into which electrolytes can be incorporated.

Previous versions of twistrons were highly elastic, which the researchers accomplished by introducing so much twist that the yarns coil like an overtwisted rubber band. Electricity is generated by the coiled yarns by repeatedly stretching and releasing them, or by twisting and untwisting them.

In the new study, the research team intertwined three individual strands of spun carbon nanotube fibres to make a single yarn, similar to the way conventional yarns used in textiles are constructed.

“Plied yarns used in textiles typically are made with individual strands that are twisted in one direction and then are plied together in the opposite direction to make the final yarn. This heterochiral construction provides stability against untwisting,” said Dr. Ray Baughman, director of the Alan G. MacDiarmid NanoTech Institute at UT Dallas and the corresponding author of the study.

“In contrast, our highest-performance carbon-nanotube-plied twistrons have the same-handedness of twist and plying — they are homochiral rather than heterochiral,” said Baughman, the Robert A. Welch Distinguished Chair in Chemistry in the School of Natural Sciences and Mathematics.

In experiments with the plied CNT yarns, the researchers demonstrated an energy conversion efficiency of 17.4 per cent for tensile energy harvesting and 22.4 per cent for torsional energy harvesting. Previous versions of their coiled twistrons are said to have reached a peak energy conversion efficiency of 7.6 per cent for tensile and torsional energy harvesting.

“These twistrons have a higher power output per harvester weight over a wide frequency range – between 2Hz and 120Hz – than previously reported for any non-twistron, material-based mechanical energy harvester,” Baughman said in a statement.

According to Baughman, the improved performance of the plied twistrons results from the lateral compression of the yarn upon stretching or twisting. This process brings the plies in contact with one another in a way that affects the electrical properties of the yarn.

“Our materials do something very unusual,” Baughman said. “When you stretch them, instead of becoming less dense, they become more dense. This densification pushes the carbon nanotubes closer together and contributes to their energy-harvesting ability. We have a large team of theorists and experimentalists trying to understand more completely why we get such good results.”

The researchers found that constructing the yarn from three plies provided the optimal performance.

The team conducted several proof-of-concept experiments using three-ply twistrons. In one demonstration they simulated the generation of electricity from ocean waves by attaching a three-ply twistron between a balloon and the bottom of an aquarium filled with salt water. They also arranged multiple plied twistrons in an array weighing 3.2mg and repeatedly stretched them to charge a supercapacitor, which then had enough energy to power five small light-emitting diodes, a digital watch and a digital humidity/temperature sensor.

The team also sewed the CNT yarns into a cotton fabric patch that was then wrapped around a person’s elbow. Electrical signals were generated as the person repeatedly bent their elbow, demonstrating the potential use of the fibres for sensing and harvesting human motion.

The team, assisted by researchers from Xi’an Jiaotong University and Wuhan University in China, Hanyang University in South Korea, and Lintec of America Inc.’s Nano-Science & Technology Center – have applied for a patent based on the technology.