An electrochemically powered artificial muscle made from twisted carbon nanotubes contracts more when driven faster thanks to a novel conductive polymer coating. The device, which was developed by Ray Baughman of the University of Texas at Dallas in the US and an international team of collaborators, overcomes some limitations of previous artificial muscles, and could have applications in robotics, “smart” textiles and heart pumps.

Carbon nanotubes (CNTs) are rolled-up sheets of carbon with walls as thin as a single atom. When twisted together to form a yarn and placed in an electrolyte bath, these hollow carbon cylinders can be made to expand and contract in response to electrochemical inputs, much as a human or animal muscle does. In a typical setup, a voltage difference, or potential, between the yarn and a counter electrode drives ions from the electrolyte into the yarn, causing the “muscle” to actuate.

While these electrochemically driven CNT muscles are highly energy efficient and extremely strong – they can lift loads up to 100,000 times their own weight – they do have limitations. The main one is that they are bipolar, meaning that the direction of their movement switches whenever the potential drops to zero. This effect reduces the overall stroke of the actuator. Another drawback is that the muscle’s capacitance – that is, its ability to store the charge it needs to expand or contract – decreases when the potential is scanned more quickly, which also causes the stroke to decrease.

Polymer “guest”

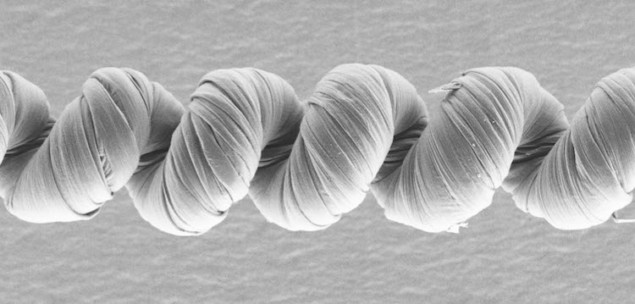

In this study, as in their previous work, Baughman and colleagues created their artificial muscle from a “forest” of CNTs all vertically aligned in the same direction. Next, they drew a thin sheet of nanotubes from the forest and twisted it to make a yarn containing helices of intertwined CNTs. In the final step, which was unique to this series of experiments, they coated the interior surfaces of the CNTs with an ionically conducting polymer that contains either positively or negatively charged chemical groups.

The first polymer “guest” material the group studied was poly(sodium 4-styrenesulphonate), PSS. The resulting structure is known as a PSS@CNT yarn and contains around 30 percent PSS by weight. To determine the zero-charge potential of this yarn – that is, the potential at which the stroke switches direction – the researchers used a technique called piezoelectrochemical spectroscopy, which they developed themselves. They then tested their yarns in baths of either aqueous or organic electrolytes.

Bipolar to unipolar

Baughman and colleagues, who report their work in Science, found that the polymer coating converts the normally bipolar actuation of CNT yarns into unipolar actuation. In other words, the coated muscle actuates in only one direction over the entire potential range at which the electrolyte remains stable.

The team’s explanation for this unusual behaviour is that the dipolar field of the polymer shifts the yarn’s zero-charge potential to a value that lies outside the electrolyte’s stability range. This means that ions of only one polarity (positive or negative) are driven into the yarn, explains team member Zhong Wang. Hence, the muscle’s stroke changes in only one direction before the direction of voltage change reverses. Team member Jiuke Mu adds that the number of electrolyte molecules that are electro-osmotically pumped into the muscle also increases the faster the potential is changed, or scanned, across its range.READ MOREArtificial muscles go with the twist

As for the new unipolar muscles’ performance, the researchers found that the maximum average output mechanical power they generate is 2.9 W per gram of muscle. This is about 10 times the typical capability of human muscle, Mu says, and about 2.2 times the weight-normalized power capability of a turbocharged V-8 diesel engine.

Dual-electrode, all-solid-state yarn muscle

In the final stage of their research, the scientists demonstrated that they could combine two different types of unipolar yarn muscles to make a dual-electrode, all-solid-state yarn muscle, thereby dispensing with the need for a liquid electrolyte bath. Here, Wang explains that a solid-state electrolyte laterally interconnects two coiled CNT yarns containing different polymer guests – one with negatively-charged substituents, and the other with positively charged ones. The injection of positive and negative ions means that both yarns contribute to actuation during charging, Wang says. He suggests that such dual electrode unipolar muscles could, in the future, be woven together to make actuating textiles that “morph” in response to electrical stimuli.

Members of the team, which includes scientists from the University of Illinois at Urbana-Champaign, Changzhou University, Jiangsu University, the Harbin Institute of Technology, Hanyang University, Seoul National University, Deakin University, the University of Wollongong, Opus 12 and MilliporeSigma, now plan to exploit these muscles in robots and artificial limbs as well as textiles.